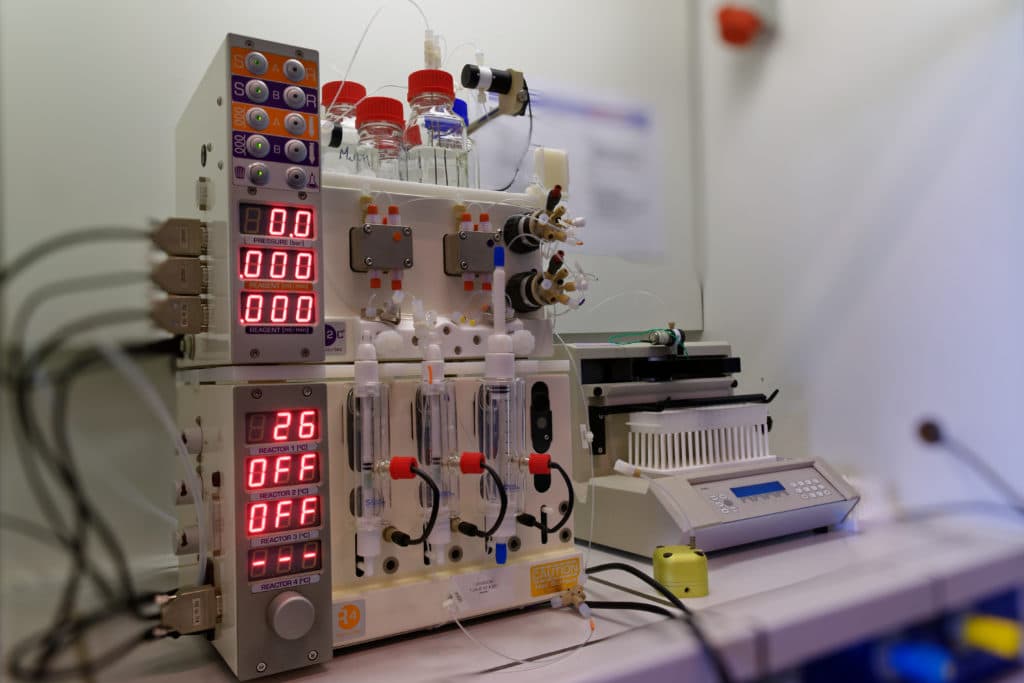

For several years, Certech has been investing in flow microreactors for process intensification and flow chemistry to develop and promote more efficient, agile, safe and sustainable solutions for the chemical industry. Applications range from organic and inorganic synthesis to chemical recycling, including heterogeneous catalysis and biocatalysis.

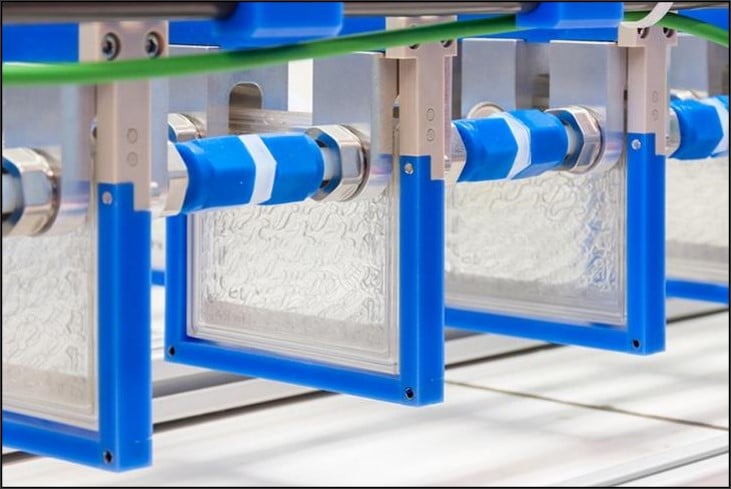

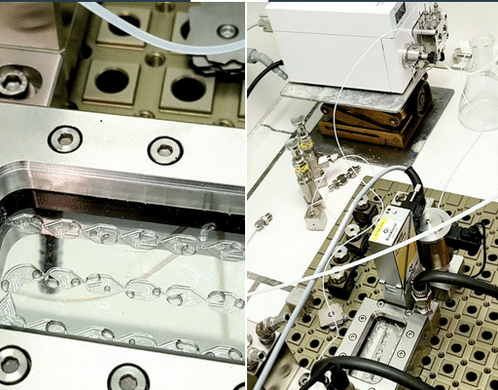

In addition to the intensified reactors designed specifically (and confidentially) by us, Certech has various commercial micro/mesofluidic reactors (flow microreactors) in order to cover a wide spectrum of applications.