Certech expertise ranges from materials development (formulation, synthesis, blending…) to processing, allowing to propose a wide variety of technical and scientific support to partners and customers looking for a global expertise in the field of material science.

Bio-based Polymers & Composites

Our services include:

- Formulation of oil-based or biobased thermosets and thermoplastics. Specific examples include wood/plastic composites, nanocomposites, barrier materials for packaging and transport, functional additives, formulations of biopolymers…

- Analysis and reverse engineering: determination of the chemical composition of resins and polymers, characterisation of molecular architectures, analysis of multi-layer materials, identification of contaminants/defects, additives, pigments and fillers…

- The determination of physical, mechanical, rheological, thermal, morphological, barrier and sensorial properties combined with statistical tools to optimise the experimental approach and results analysis.

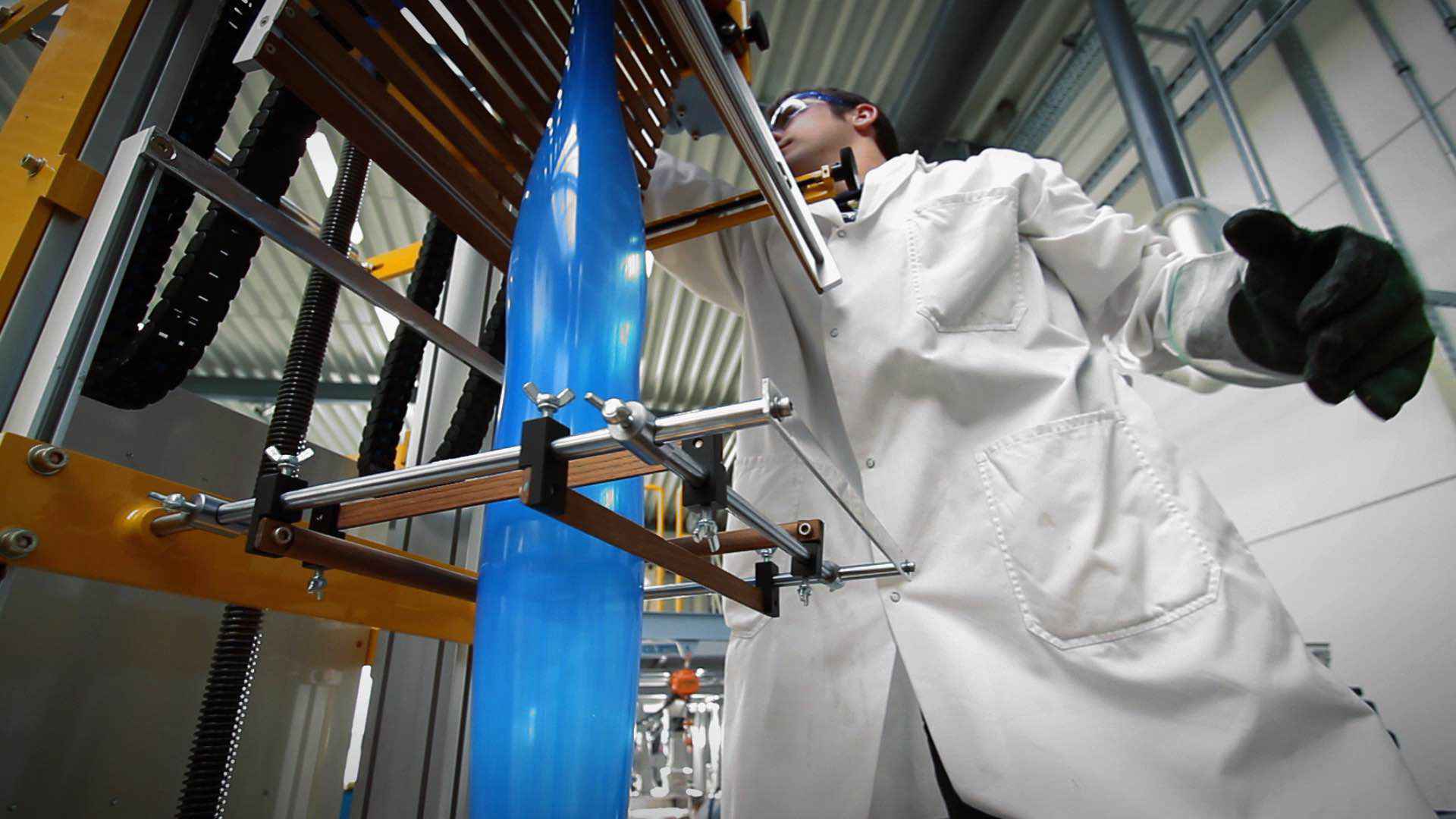

Certech processing hall comprises all main processing techniques for thermoplastic materials :

- Pre-treatment : air dryers, compactor for producing pellets, grinder

- Mixing and compounding : single-screw and twin screw extrusion

- Shaping : cast film extrusion, blown film extrusion, foam extrusion, filament extrusion calibrated for 3D printing, thermoforming, compression molding, injection molding, fiber impregnation, micro twin screw extruder and microinjection molding (5 g)

Thermoset processing techniques like LRI (Liquid resin Infusion) and 2 component resin transfer moulding (2KRTM) are also available.

Certech has also developed an expertise in the field of raw material substitution for plastics and composites. The objective is to replace components which are raising either sustainability or public health issues.